Name: Quashif Qureshi

Guide: Prof GG Ray and Prof N Sadhu

Course: Industrial Design

Credits: Tata Center Technology and Design, IIT Bombay

Ergonomics intervention in traditional brick making industry on removal of drudgery and developing safe work conditions towards enhancement of productivity

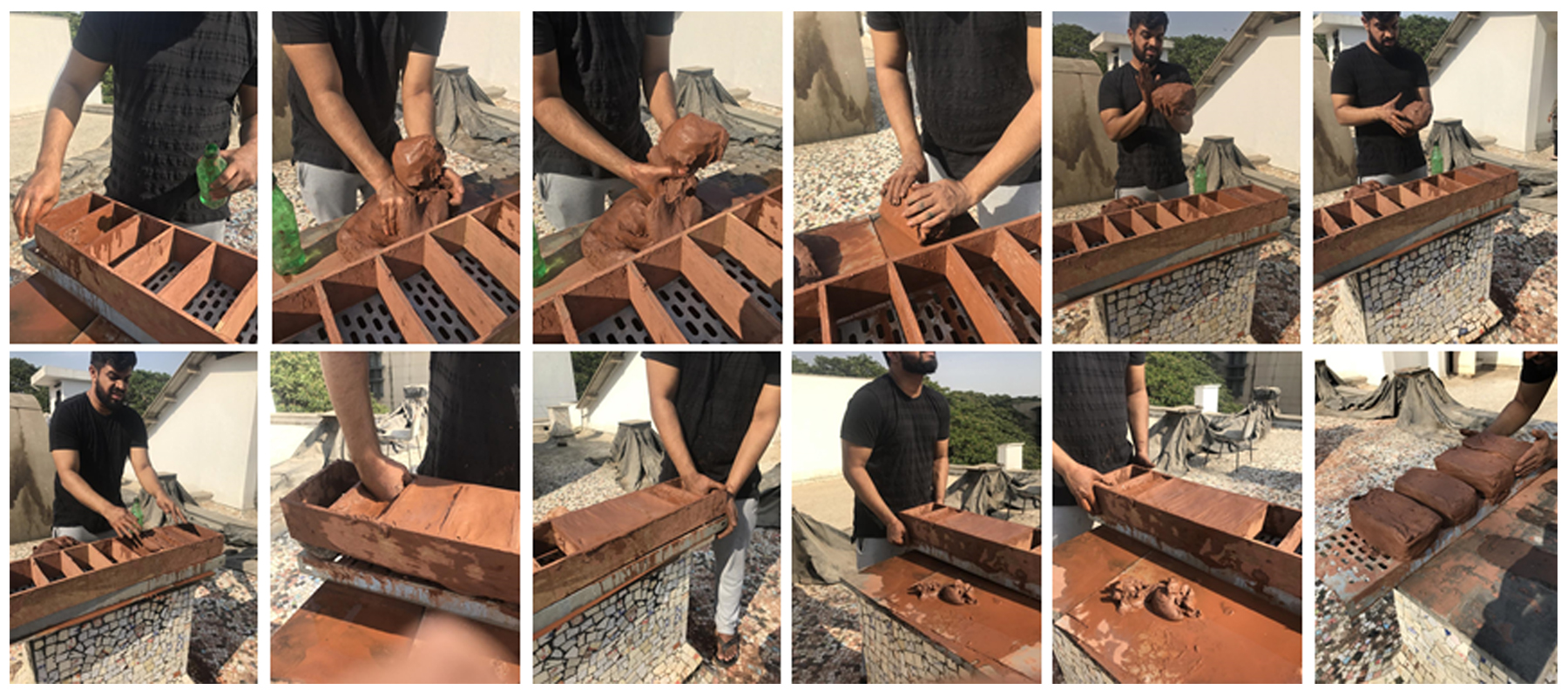

Brick manufacturing in India is a traditional and unorganised industry. Of late, due to rapid urbanisation, the concept of high rise metropolises and spurt in real estate development, brick making has become one of the flourishing industries. There are more than 22,000 brick kilns in India engaging more than 3 million workers. The process of brick making involves six major activities, such as mud preparation, moulding, carrying raw bricks to brick kiln, arranging raw bricks inside the kiln for firing, firing of raw bricks and carrying out fired red bricks from brick kiln. It becomes vital to consider the system complexity, worker’s literacy level, work related drudgery, awareness of both workers and management on occupational health and safety.

The present proposal is aimed for making the work more human by focusing the issues of three major operations, viz., mud preparation, brick moulding and brick firing/Jalai among six operations.

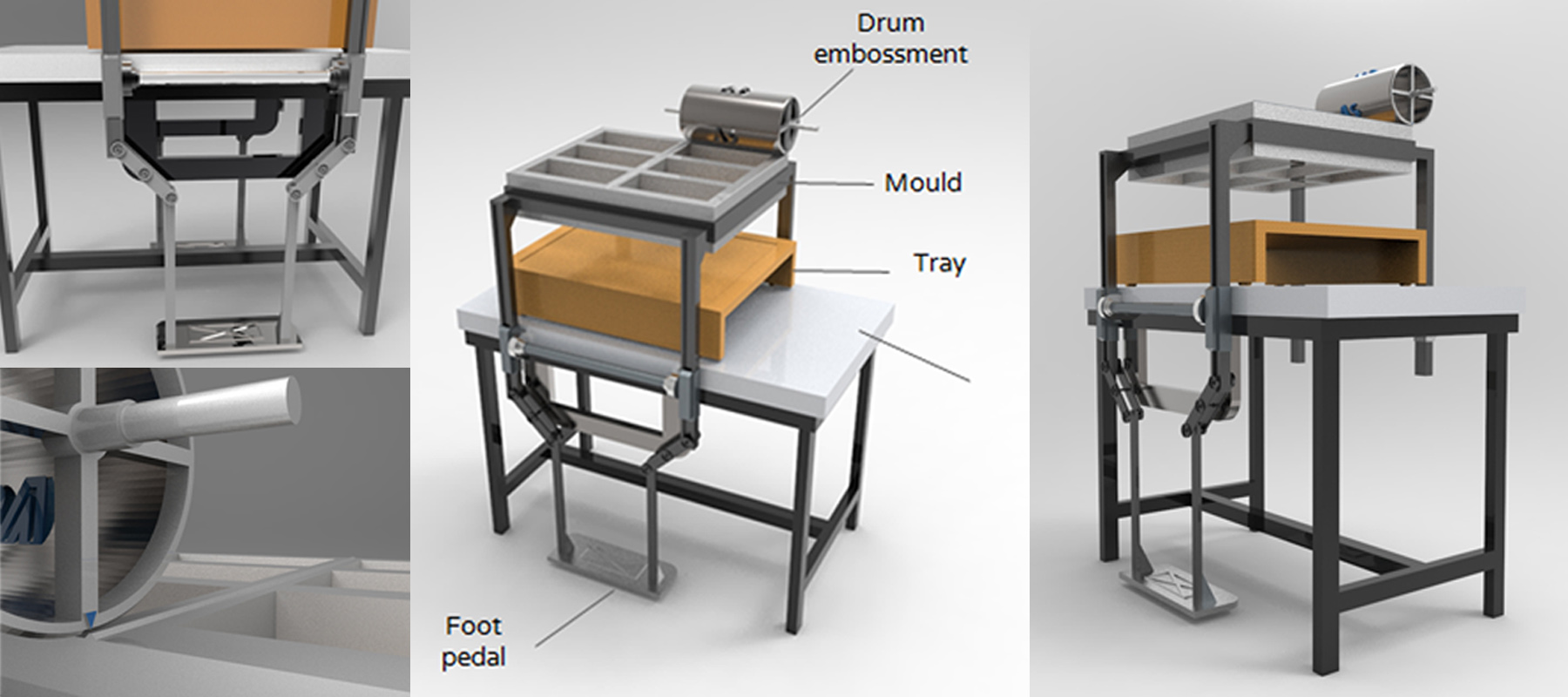

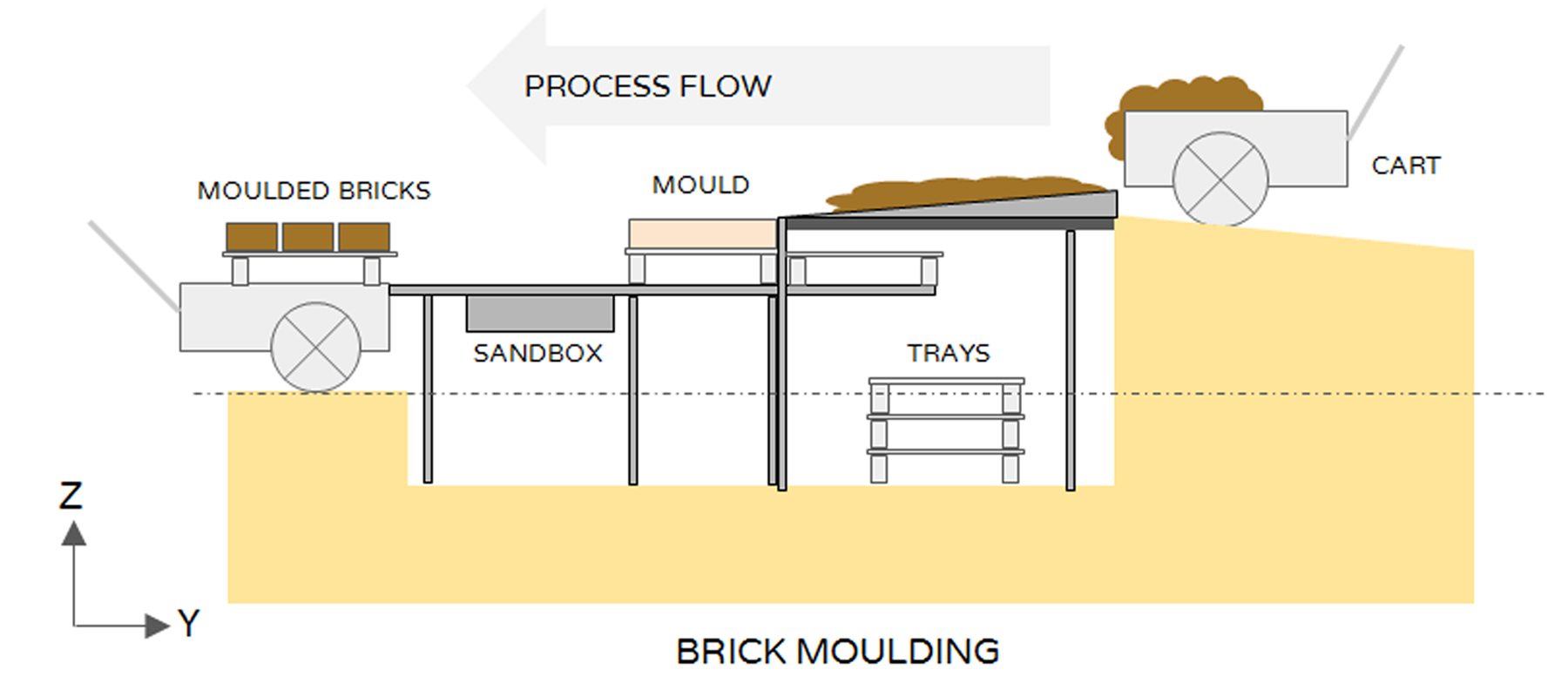

The project addresses the Issues related with the brick moulding process by using system level design to reduce drudgery involved with the mud loading action, brick moulding action and brick transfer and to increase the productivity by designing frugal workstation keeping in mind that the livelihood of the workers associated with the job should not get replaced by machines as well as keeping the cost of the whole setup as low as possible.

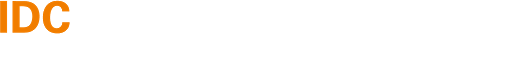

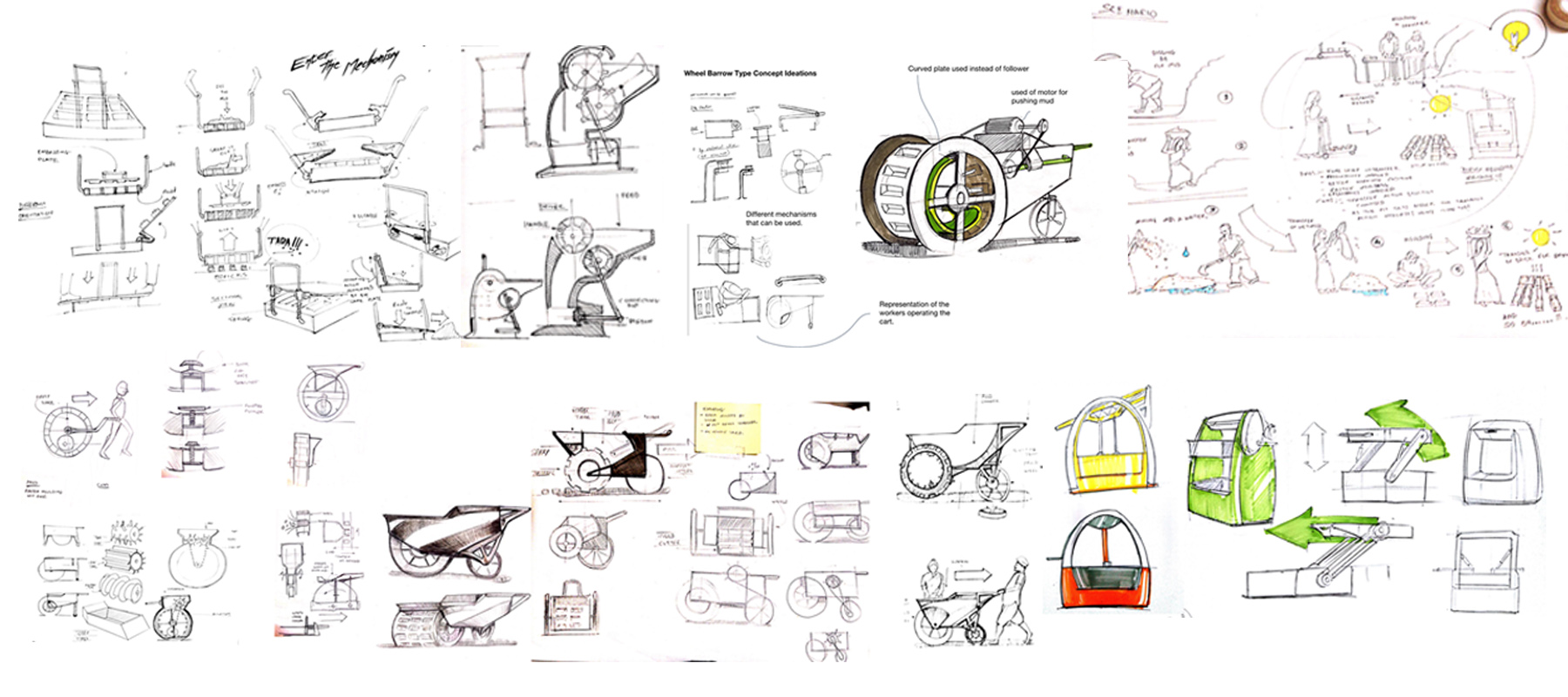

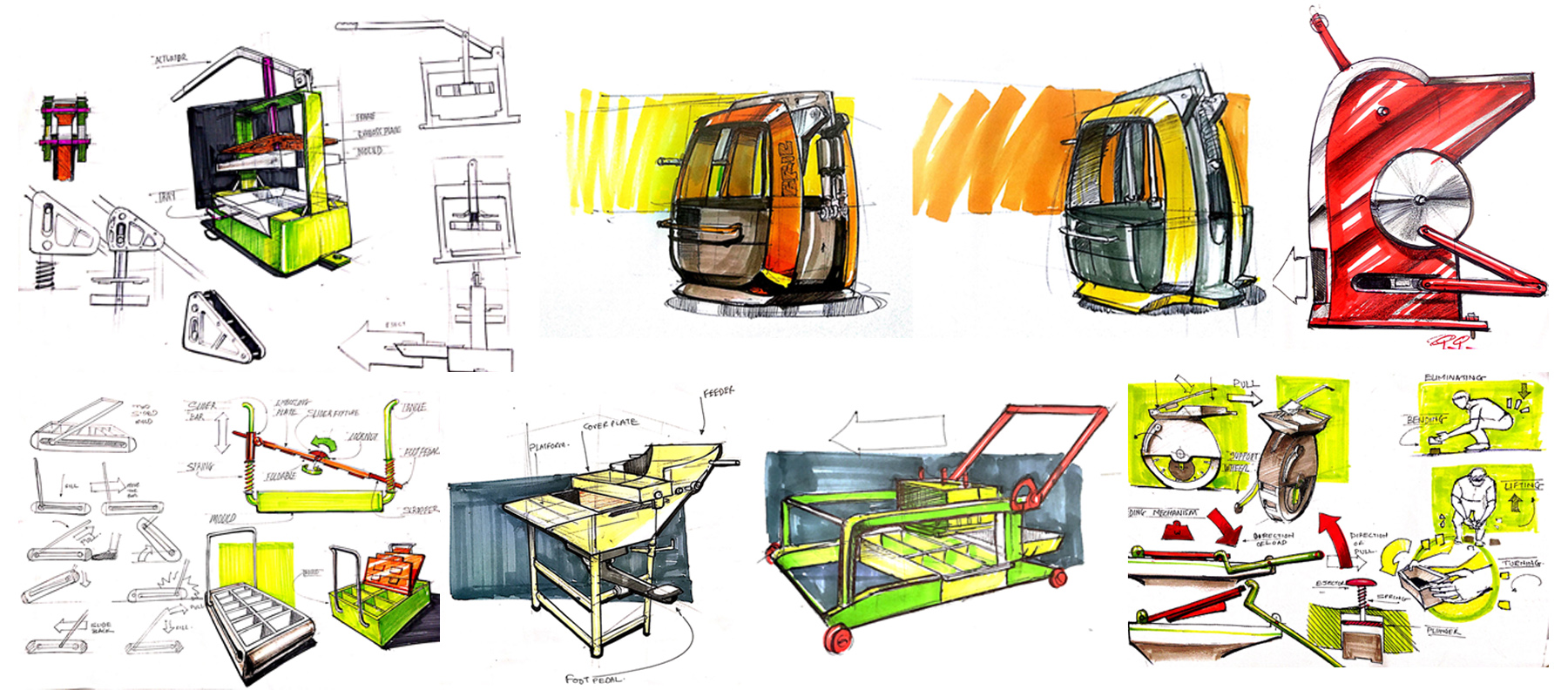

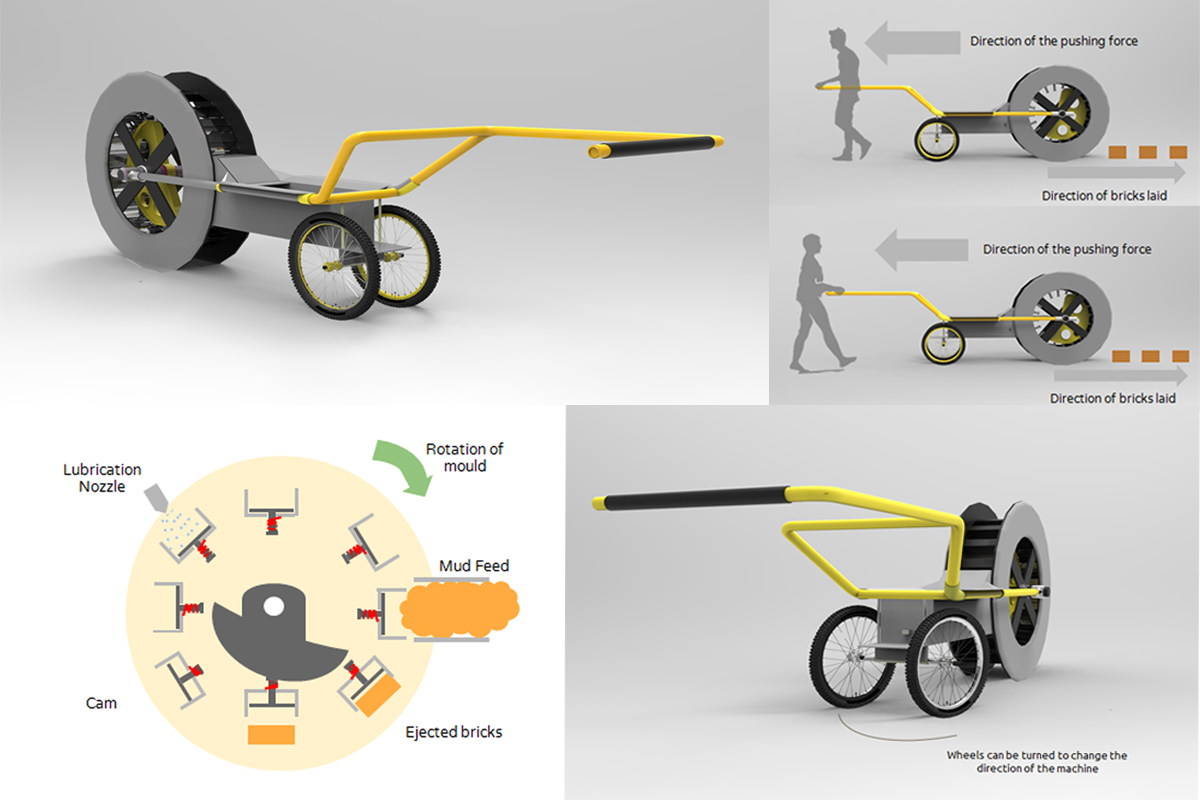

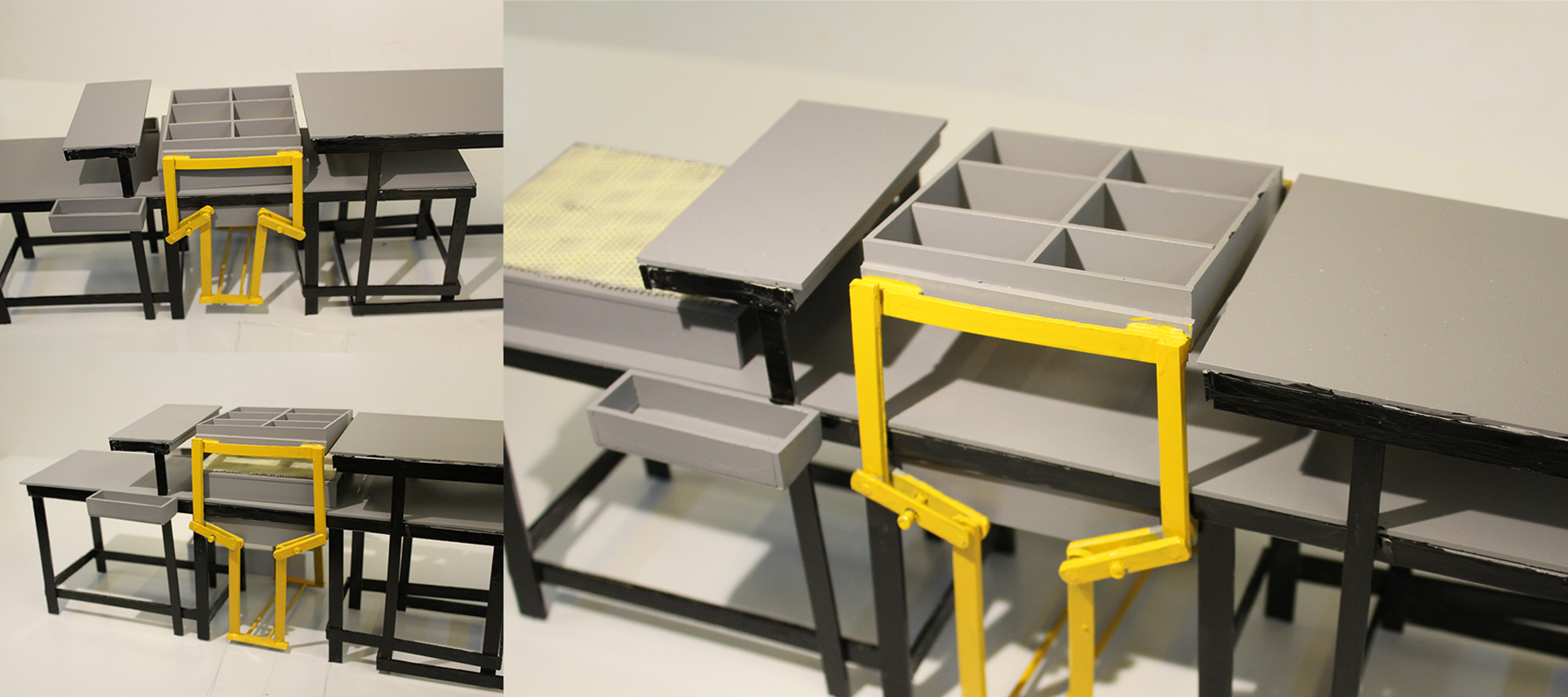

Based on brainstorming exercise and inputs from experts, various ideations and concepts were created to find the most optimum design to address the problem.

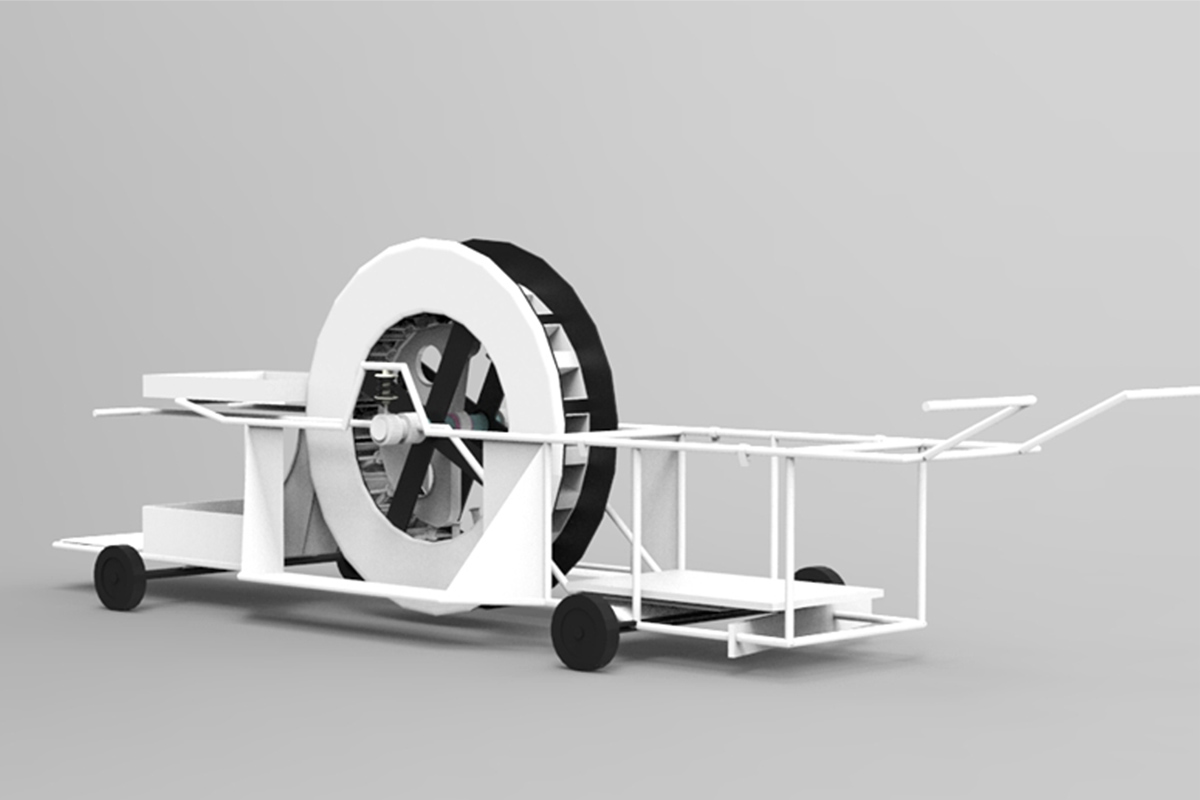

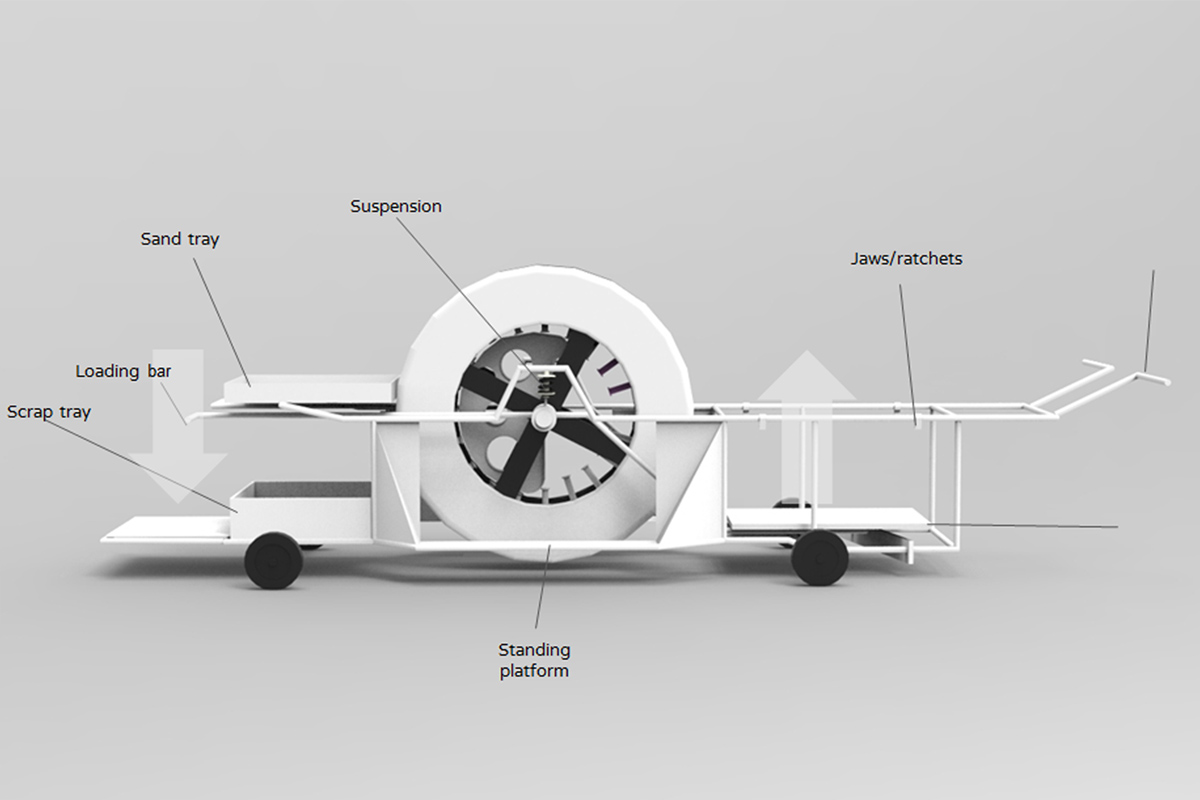

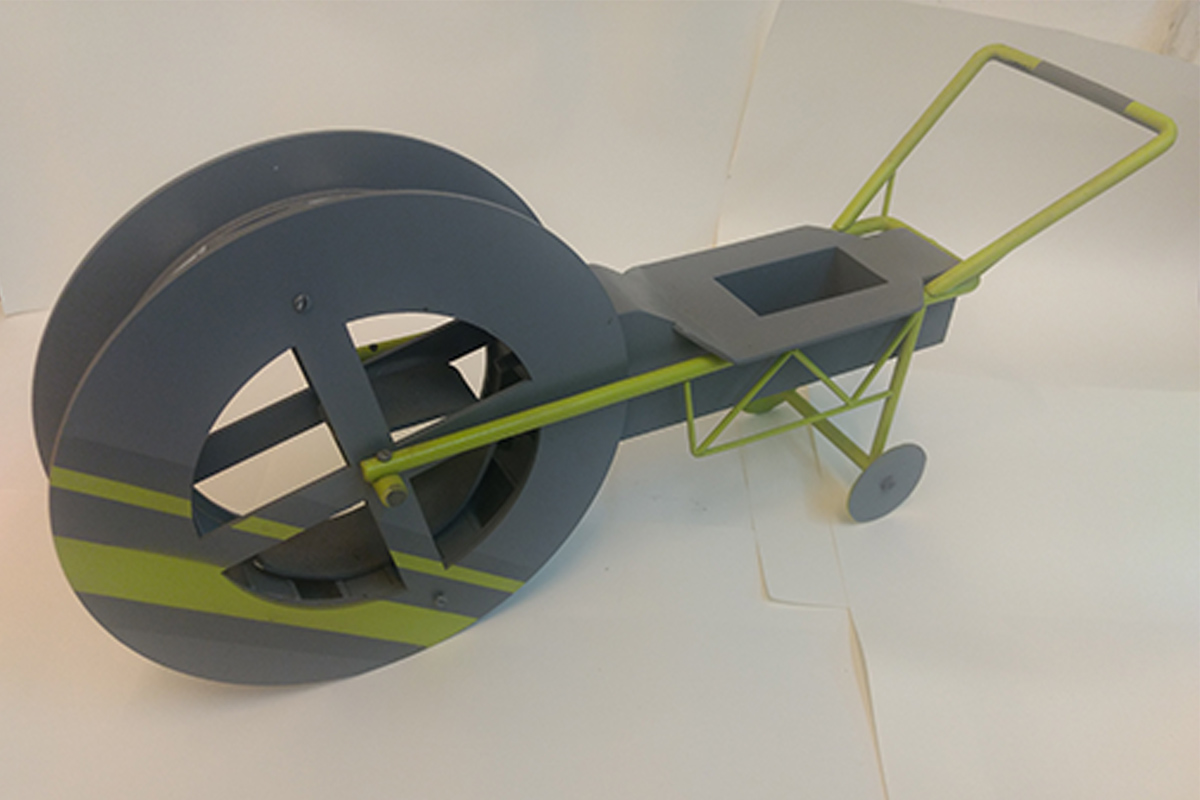

After validation and different design condsiderations, this concept of a semi automated pull cart type brick moulding was selected, which gave the workers an ability to lay bricks directly on the ground without bending their bodies. The machine consist of a rolling drum with brick moulds with plungers installed in it ,they get actuated when they come on in the contact of the cam plate located at the bottom dead centre of the drum resulting in laying of bricks directly on the ground.

The observations from the previous design interventions motivated me to make a more minimal machine which can be frugal, easy to maintain and a machine which does not replace their traditional brick making skills. This particular design made brick making possible in a more minimal and simplistic way involving a more ergonomic, mechanical and system level designs.